With this instrument, both-way slide testing and wear tester can now both be tested with one instrument. Not only does this benefit both parties, but the wear testing has also become more simplified. The H34’s automatic both-way movement has a maximum of 9,999,999 movement number of times. This system also utilizes a dedicated chucking jig as its drum roller fixing method and has rotation direction/speed of 50-500rpm.

SKU

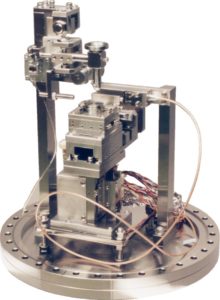

H34

Categories Friction, Wear and Surface Property Analyzers

$54,900.00